The hunt for carbon-neutral ways of meeting the increasing demand for energy is all-consuming. With the imminent threat of global warming as a backdrop, sustainable energy production is on the top of the agenda for both local and global governments.

Offshore wind power is one of the fastest-growing sources of renewable energy and is expected to play an increasingly significant role as oil and gas production is phased out. While bottom-fixed wind turbines have been widely installed already, the floating wind industry is on an uprise.

A major advantage of floating wind turbines is that they allow us to access remote locations with larger water depths, offering vast areas with large prevailing wind speeds. Meanwhile, the Norwegian oil and gas industry has great ambitions and targets a 50% reduction in carbon emissions by the year 2030.

Innovation is needed

One of the ways to achieve this is by electrifying the installations using power from floating wind farms. This will also offer the possibility to mature the floating wind industry and bring down the cost of energy, which will eventually be crucial for its success.

However, there are challenges to overcome: floating wind farm developments must become less expensive to compete with other sources of energy, and the local and global environmental impact must be reduced. Honeymooring offers a solution for both these challenges.

Fiber-ropes instead of steel chains

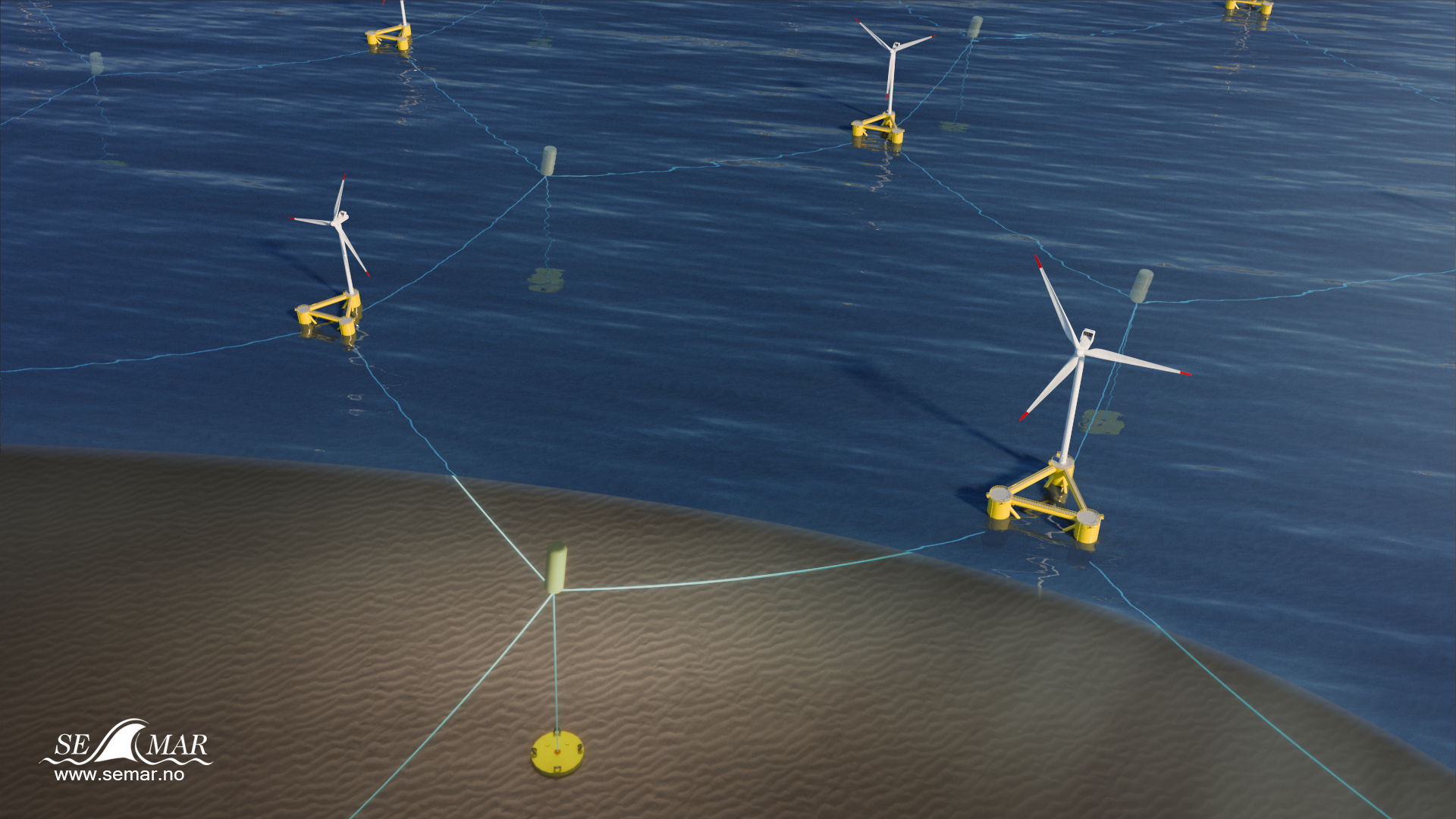

In simple terms, Honeymooring is a system for mooring floating wind turbines in a honeycomb network. Each floating wind turbine is connected to shared buoys using light, horizontal fiber ropes, and each buoy is moored to the seabed using a taut fiber-rope mooring line. In this way, Honeymooring enables sharing of anchors in a way that is easily scaled for different water depths.

By eliminating the use of steel chains, Honeymooring reduces capital expenditures by lowering procurement and installation costs. Using fiber ropes instead of steel chains, which are energy-intensive to produce, lowers the CO2 emissions of the park. Moreover, no chain on the seabed means that unfavorable consequences for the local ecosystem are avoided. The Honeymooring technology, therefore, lowers the cost of energy from floating wind farms, and at the same time minimizes the environmental impact.

Honeymooring reduces the cost of mooring hardware in three main areas

- Light and cheap fiber-ropes mooring lines replace heavy and costly steel chains.

- Extensive use of shared moorings reduces the number of system components.

- With the reduced weight of mooring lines and low pretension levels in the system, cheaper installation vessels can be used.

However, cheaper does not mean less safe. Using fiber ropes in permanent mooring systems represents proven technology. The novelty introduced by Honeymooring is that the lines are part of a shared mooring system, where the failure modes may differ from a traditional standalone system.

Defining these failure modes, and demonstrating that the system operates at the required safety level, is part of our ongoing activity.

A sufficiently redundant system is key

In the design of floating projects, it is of key importance that failure of a single component does not lead to a progressive collapse of the entire farm, and it is, therefore, a key priority in the ongoing Honeymooring development to design a system that is sufficiently redundant.

An advantage of Honeymooring in this respect is that the anchor forces are distributed evenly throughout the wind farm. This means that excessive loads are not concentrated on any single buoy or anchor.

Therefore, the system can be designed with sufficient spare capacity to ensure that the consequence of a line or buoy failure is acceptable.

On the path to an accelerated technology qualification

When governments make large-scale developments possible, we want Honeymooring to be fully qualified and ready for use. By doing so, we wish to contribute to the commercial success of the floating wind farm industry.

The floating wind industry will require a substantial supply chain and will create many jobs in the process. In realizing Honeymooring as a concept, we shall collaborate with Norwegian partners, where the aim is to succeed together.

Semar is presently devoting substantial research and development efforts to maturing the Honeymooring technology. In this process, we are simultaneously building a study environment around Honeymooring as a concept with specialist competence coupled with extensive analytics.

Guidelines and collaboration to ensure future success

At the same time, we support industry activities devoted to establishing guidelines and industry practices for floating wind farms. Such efforts are important to secure the future success of floating wind, and we believe that these challenges are best solved by working together as an industry.

We are always on the look for enthusiastic partners to join our Honeymooring adventure. If you are interested in learning more about the concept, we would love to get in touch.

Reducing mooring hardware costs is just one of the many benefits of using Honeymooring instead of traditional mooring systems. Read all about it in our free quick guide! 👇